Excavator Bucket Teeth & Adapters for Sale

Excavator bucket teeth and adapters are crucial components in the construction and excavation industry. These parts are essential for the digging and cutting functions of excavators.

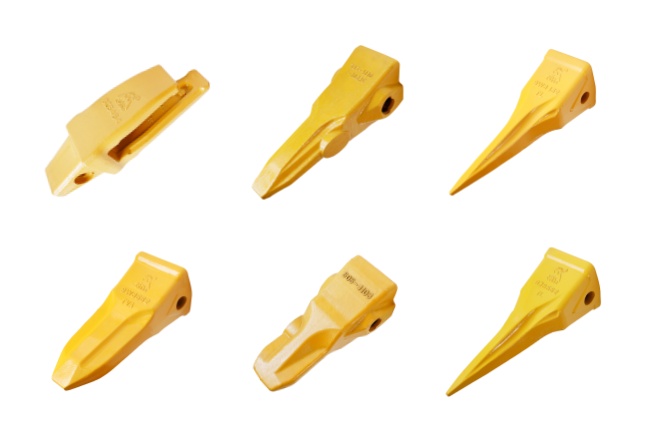

Excavator Bucket Teeth:

Bucket teeth are the pointed or chisel-like structures attached to the edge of an excavator bucket. They are responsible for breaking and digging into the soil, rocks, or other materials. It is typically made of high-strength steel or other wear-resistant materials to withstand the harsh conditions of excavation.

Bucket teeth are an important part of an excavator. They loosen the material and prevent the bucket from scratching the ground. There are many different types of bucket teeth, each developed for a specific application. Choosing the right bucket tooth helps reduce wear. Our team of experts will be happy to find the perfect bucket tooth for your bucket. You will be satisfied.

Various bucket tooth types

Technical experts to help you keep going

High-quality bucket teeth with a long service life

We offer our customers bucket teeth from well-known brands such as KOMATSU, CATERPILLAR, DEVELON, LONKING, SANY, VOLVO, etc., which are suitable for various applications. The brands we deliver are available in our online shop.

Didn’t find what you are looking for? Contact us now, we will be happy to help you.

Adapters:

Adapters serve as the link between the bucket teeth and the excavator bucket. They are designed to provide a secure connection while allowing for easy replacement of bucket teeth when they wear out. Similar to bucket teeth, adapters are also made from durable materials such as high-grade steel to ensure longevity and resistance to wear and tear.

Types of Teeth and Adapters:

Standard Teeth: These are the regular, pointed teeth used for general-purpose digging.

Rock Teeth: Specifically designed for digging in rocky or abrasive terrains, these teeth are more robust and have enhanced wear resistance.

Adapters: There are various types of adapters, including weld-on adapters and bolt-on adapters. Bolt-on adapters allow for easier replacement when teeth are worn, while weld-on adapters provide a more permanent attachment.

Installation and Maintenance:

Installation: Excavator bucket teeth and adapters are typically attached using bolts or welding, depending on the type. Proper installation is crucial to ensure a secure connection and optimal performance.

Maintenance: Regular inspection and maintenance are essential to identify worn-out teeth and adapters. Prompt replacement of these components can prevent further damage to the excavator bucket and ensure efficient excavation.

Excavator Bucket Teeth Manufacturer

Bucket teeth are the key tooth tips or sharp corners of heavy machinery such as excavators, loaders and backhoes. They are able to effectively penetrate and break hard materials such as soil, rocks and debris. When working, the bucket teeth are mounted to the tooth holder through pins and then fixed to the front edge of the bucket. As the bucket teeth wear, they can be replaced regularly to ensure efficiency. Bucket teeth play an important role in construction, mining and earthmoving applications.

G-TOP is a professional bucket tooth manufacturer. In order to improve the wear resistance of bucket teeth, we use high-strength alloy steel to produce bucket teeth so that they can withstand long-term wear and extend their service life. We have more than 2,000 sets of molds and use investment casting technology to produce bucket teeth of various shapes and can be assembled with buckets of different specifications.

Bucket Teeth Material

The bucket teeth castings we produce are made of low alloy steel, with the main components of carbon, silicon, manganese, chromium, aluminum, etc. In addition, in order to improve wear resistance and working performance, we recommend adding trace elements such as molybdenum and nickel. The following are the detailed chemical composition and mechanical properties of our cast bucket teeth.

Our Investment Casting Manufacturing Process for Bucket Teeth

Bucket teeth are G-TOP’s most iconic casting product. Many people are familiar with the purpose of bucket teeth, but they may not be familiar with the manufacturing process.

To ensure high precision and excellent mechanical properties, we use an investment casting process to manufacture various types of bucket teeth. The investment casting process used by G-TOP ensures the production of high-quality bucket teeth with excellent durability, precision and performance, making them ideal for demanding construction and excavation applications. The following is a breakdown of the steps of our foundry’s bucket tooth manufacturing process.

Step 1: Making a wax pattern

Making a wax pattern is the first step to begin investment casting bucket teeth. The process of making a wax pattern is to quickly inject wax into a mold. These wax patterns are exact replicas of the bucket teeth. The quality of the wax pattern will directly affect the accuracy of the bucket teeth, so it is crucial to check the quality of the wax pattern before moving on to the next step.

Step 2: Assemble into a tree

Once the wax pattern is ready, it will be attached to a central wax rod to form a structure called a “tree”. This wax tree will contain multiple wax bucket tooth models, allowing multiple parts to be cast at the same time, thereby improving efficiency.

Step 3: Ceramic Shell Construction

The wax tree is repeatedly dipped into the ceramic slurry and covered with fine sand to form a ceramic shell around the wax model. This shell is built up layer by layer until the desired thickness and strength are achieved. CFS Foundry ensures a controlled drying process so that each layer hardens sufficiently, resulting in a strong, high-temperature resistant ceramic mold.

Step 4: Dewaxing

Once the ceramic shell is complete, the next step is to heat the shell in an autoclave to remove the wax mold. The wax melts and flows out at high temperatures, leaving a hollow ceramic mold. This step is called the dewaxing process, and the result is a cavity similar in shape to the tooth.

Step 5: Metal Pouring and De-Shelling

The next step is to melt the solid metal into a liquid state and pour it into the cavity of the shell. The metal cools rapidly and solidifies, forming the solid shape of the tooth. CFS Foundry uses high-quality alloys to ensure that the finished tooth is tough and wear-resistant, providing the strength required for digging tasks. The shell is then disassembled to remove the tooth.

Step 6: Heat treatment and surface treatment

Heat treatment is also an important step in the production process of bucket teeth. The heat treatment process includes quenching and tempering. Quenching can further improve the hardness of bucket teeth, while tempering can adjust the toughness and impact resistance of bucket teeth. After heat treatment, bucket teeth are shot peened to make their surface smooth and painted for rust prevention.

Why buy bucket teeth from G-TOP?

Advanced casting process: There is another casting process, coated sand casting (referring to investment casting and sand casting), which is used to manufacture bucket teeth with lower cost. However, due to its poor quality, many quality problems often occur, such as poor surface finish, insufficient wear resistance, short service life, etc. All these quality problems will lead to frequent replacement of bucket teeth, which is not only uneconomical, but also increases costs.

Best performance: The unique material combined with excellent heat treatment process, our bucket tooth tip can minimize wear. The innovative bucket tooth shape keeps it sharp at all times, which helps to speed up bucket loading. In addition, our lateral thickening design makes the product more wear-resistant and durable!

Perfect appearance: Even with the same production process, the appearance of the product will be different. G-TOP not only pays attention to the inner quality, but also pays more attention to the surface finish. With rich production experience, we continue to improve the investment casting process, strive to achieve good surface quality in every process, and minimize welding repairs. In addition, we use first-class spray painting technology with different colors to ensure that the product is shiny and clear.

FAQs

Are you a factory or a trading company?

G-TOP is a leading manufacturer and exporter of high-quality wear parts for large heavy machinery in China. We are committed to providing long-lasting and durable solutions for heavy machinery in the mining, quarrying, agriculture, public works and construction industries. We also provide other ground working tools, such as bucket teeth, adapters, cutting edges and end bits etc. These products are suitable for various construction and mining machinery, such as excavators, graders, bulldozers, scrapers, etc.

Can you make bucket teeth with our specific design?

Of course, we can customize bucket teeth according to your drawings or samples. The mold is only for your production. If necessary, we can even add your logo on the surface of the bucket teeth.

Why should you choose G-TOP to complete your bucket tooth project?

First of all, G-TOP is very professional in investment casting, and we have very rich experience in producing bucket teeth and tooth adapters. We have various types of bucket teeth and can recommend the most effective solution according to the working environment.

What other services can you provide?

One-year warranty, damaged parts due to abnormal wear can be replaced free of charge.

Provide technical support to our customers.

Help you expand the market.

Provide VIP treatment for our exclusive agents.